DuctSeal FR Cable Duct Sealing System

DuctSeal FR Cable Duct Sealing System

Couldn't load pickup availability

The DuctSeal FR system is an innovative fire-resistant, low-smoke, zero-halogen duct sealing solution designed for maximum flexibility and safety in critical infrastructure.

Suitable for sealing all cable sizes, including large and heavy power cables and pipes, DuctSeal FR provides effective protection against the ingress of fire, smoke, harmful gases, flammable vapours, water, and pests.

Independently tested to BS EN 1366-3:2021 and AS 1530.4:2014, DuctSeal FR delivers proven fire protection performance while maintaining re-enterable access for future cable upgrades or maintenance.

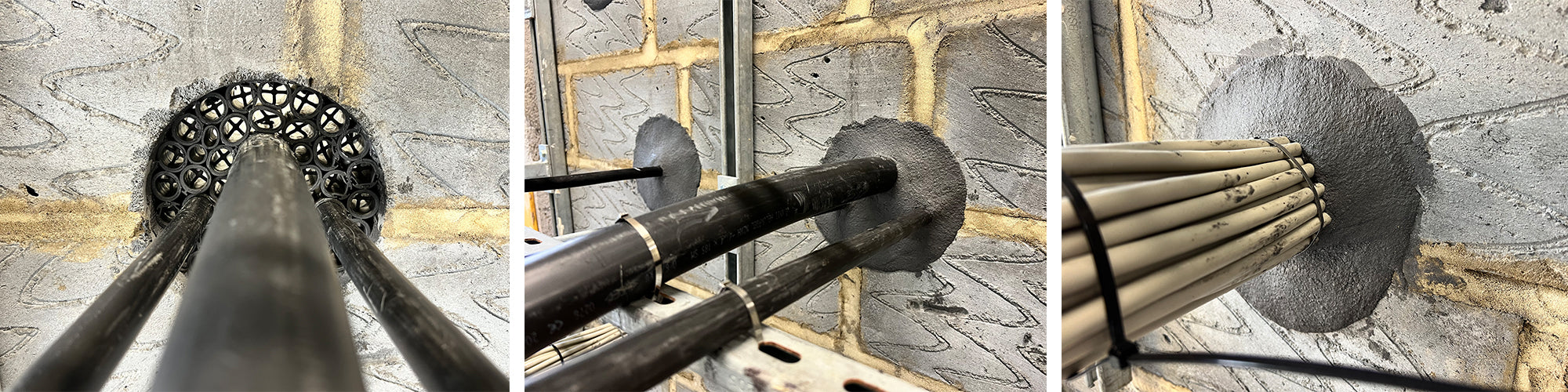

At the core of the system is our patent-pending backing design, featuring intumescent circular tubes manufactured from FireStuff – our marine-grade, fire-resistant granulate. These modular tubes can be connected, separated, or reconfigured into cross-shaped structures for trefoil/triplex cables, ensuring secure spacing and structural stability.

Once in place, the system is sealed using GreyStuff or RedStuff – advanced, flexible, intumescent sealing compounds that are zero-halogen, MEKO-free, and installer-safe. Together, this creates a robust, watertight, gas-tight, and fire-rated barrier that protects both the cable network and the surrounding infrastructure.

Proudly designed and manufactured in the UK, DuctSeal FR is trusted by water authorities, data centres, utilities, transport networks, and petrochemical industries wherever fire safety and compliance are critical.

Share

| FEATURE | Density | Colour | Skin Over Time | Curing | Tack Free Time | Hardness | Elongation | Flow | Tensile Strength | Operating Temp. | Temp. Resistance | Intumescence Activation Temp. |

Pressure Resistance | Shelf Life |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| VALUE | 1.27 | Grey or Red | 10 mins | 3-4mm per day | 22 mins | 35 to 38 Shore A | 250% | 3.33 million cPs at 380°C |

0.72N/mm² | +5 to 40°C | -35 to +120°C | 210°C | 1.0 Bar | 12 months |

Collapsible content

Key Features

Fire Resistance – Up to 4 Hours

Independently tested to BS EN 1366-3:2021 and AS 1530.4:2014, DuctSeal FR delivers proven fire protection performance for up to 4 hours, making it suitable for critical infrastructure projects.

Intumescent Technology

Both the sealant (GreyStuff/RedStuff) and the FireStuff intumescent backing sleeves expand under fire conditions, ensuring reliable sealing around cables and ducts.

Patent-Pending Trefoil/Triplex Cable Separation

Unique modular backing tubes can be connected, separated, or cross-configured to provide structural support and separation for trefoil/triplex cables – a market-leading feature for safe, compliant installations.

Low Smoke, Zero Halogen (LSZH)

Designed to minimise smoke generation and eliminate toxic halogens in the event of fire, making DuctSeal FR safe for data centres, transport hubs, and enclosed environments.

Safe, Non-Hazardous Sealant

Incorporates our advanced MEKO-free FyBrid intumescent compound, ensuring a safe, environmentally responsible installation.

Multi-Barrier Protection

Provides a combined fire-, water-, and gas-tight seal, preventing ingress of harmful elements into ducts.

Resistance to Toxic Gases

Specifically developed for the water industry, DuctSeal FR resists methane, chlorine, and hydrogen sulphide.

Hydrocarbon Resistance

Suitable for petrol forecourts and chemical environments, offering long-term durability against hydrocarbons and aggressive chemical agents.

Compliance with Key Standards

Fully compliant with DSEAR, WIMES, DCG, APEA Blue Book, and ATEX, ensuring suitability across the most demanding sectors.

Microbial Defence

Formulated with enhanced resistance against fungal and bacterial growth, ensuring long-term performance in damp or contaminated ducts.

Minimal Cable De-Rating

At a 25mm seal thickness, thermal resistance is just 5.1

K/W, allowing cables to retain their maximum current-carrying capacity.

Proudly British Made

All DuctSeal FR components are designed and manufactured in the UK, guaranteeing quality, reliability, and supply chain security.

Fire Resistance

Fire Resistance Rating: Up to 4 hours (240 minutes) fire resistance, tested in both directions.

Standards Tested: BS EN 1366-3:2021, which supersedes BS EN 1366-3:2009.

Cable Types Tested: Small, medium, large, telecommunication cables, and bundled arrangements.

Cable Specifications: NYY-O, N2XH-J, HO7V-K, J-Y(ST)Y.

Warrington Fire References: (B), (G), (D3), (F), and (E).

Penetration Size Tested: Horizontal penetrations up to 200mm (8 inches) in diameter.

Wall Construction Tested: 140mm thick low-density concrete walls (tested without ducts or sleeves).

Test Facility: Independently tested at Warrington Fire (Exova).

Sealant Test Notes

GreyStuff Sealant (Grey): Fully tested within the DuctSeal FR kit according to BS EN 1366-3:2023.

RedStuff Sealant (Red): Not fire tested, but can be used with customer/end user authorisation only.

Formulation Consistency: GreyStuff and RedStuff are chemically identical except for the pigment (<1% difference). This colour variation does not affect fire resistance, physical performance, or handling properties of the system.

Penetration Size Tested: Horizontal penetrations up to 200mm (8 inches) in diameter.

Wall Construction Tested: 140mm thick low-density concrete walls (tested without ducts or sleeves).

Test Facility: Independently tested at Warrington Fire (Exova).

Installation

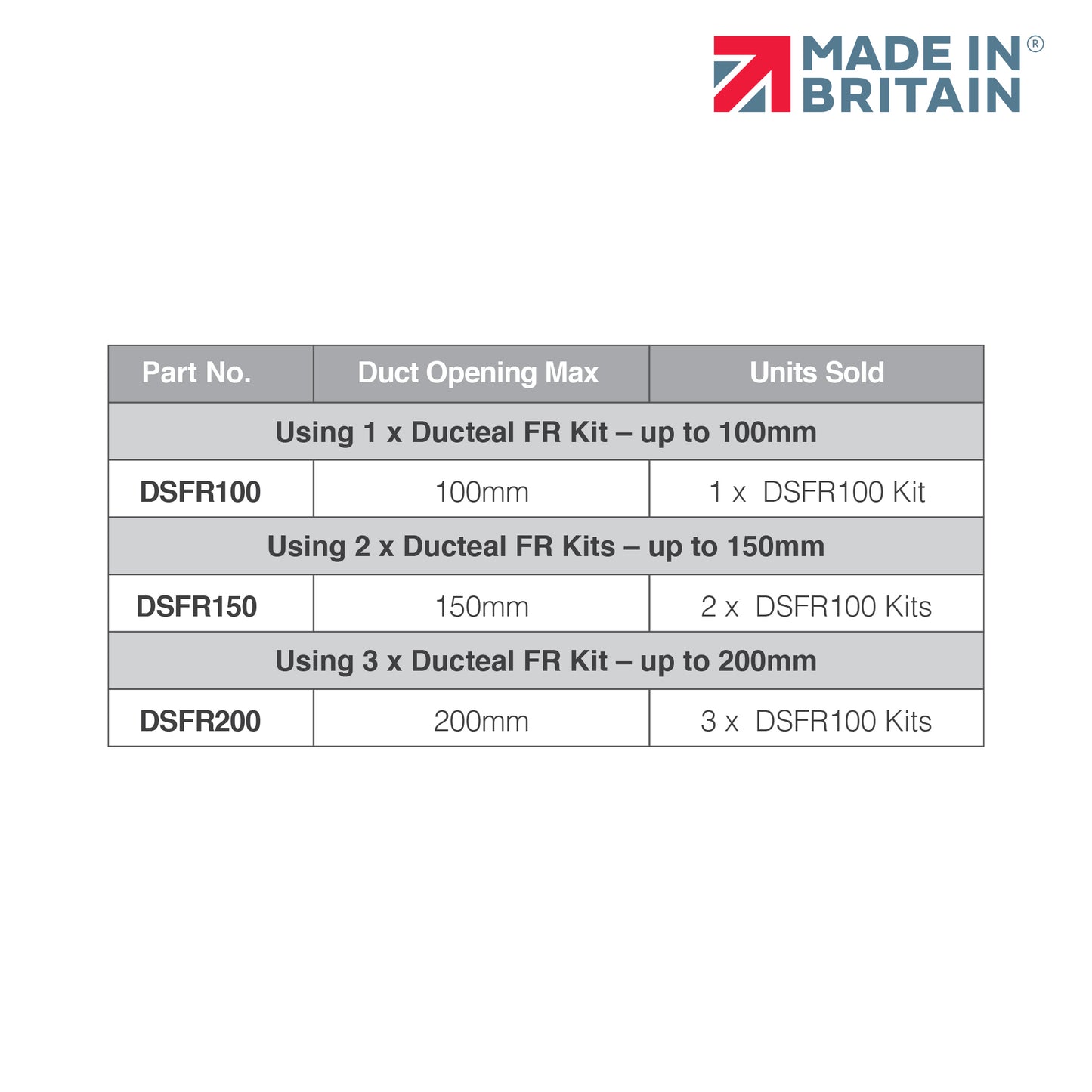

One Kit Per Duct

Each kit contains all components required to seal one duct as per the kit size specified.

Note: A standard caulking gun is required (not included, but available separately). In some cases, one kit may fill more than one duct depending on the percentage cable fill. For advice, call our technical team on +44 (0)161 874 1480.

Cable Separation & Support

Proper cable separation is essential for fire and gas-tight performance.

The daisy-chained circular tubes support single or multiple cables.

Using our patent-pending tubular intumescent tubes, installers can create different shapes (continuous strip, ring, or cross-form) to accommodate trefoil/triplex cable arrangements.

Running Water

Ducts and cables may be damp but must be free from running water. All surfaces should be cleaned of dirt, oil, or grease before applying GreyStuff or RedStuff.

Cure Time

GreyStuff and RedStuff cure at a rate of approximately 3–4mm per day, depending on humidity and temperature. Higher humidity and warmer conditions accelerate curing.

A minimum seal depth of 25mm is required to achieve effective fire, water, and gas performance.

Cleaning

Uncured material can be cleaned with a solvent-based wipe. Once cured, mechanical removal is required.

Fire Certification – Important Note

Fire resistance is only applicable to an “as fire tested” system or otherwise approved configuration. The system achieves the certified rating only when the exact tested proprietary product is installed in the same way as approved during testing.

Always ensure your installation matches our fire test certification.

End users are responsible for verifying that DuctSeal FR is the correct system for their project.

For copies of fire test reports, or to review our Duct Sealing Disclaimer, please contact our technical department.

GreyStuff vs RedStuff – Fire Resistance

GreyStuff (Grey): Tested to BS EN 1366-3:2023 as part of the DuctSeal FR system.

RedStuff (Red): Not independently tested, but can be used with customer/end user authorisation.

The only difference between the two is the pigment (<1% variation). This does not affect fire resistance, physical properties, or handling.

Health & Safety

GreyStuff and RedStuff use a neutral-curing, MEKO-free formulation, making them non-hazardous and safe for installers.

Re-Entry & Removal

Once cured, the compounds achieve a rubber-like hardness. Re-entry and removal are possible, though effort will depend on the tools used.

Always use sharp tools only on de-energised cables. AC Cable Solutions accepts no responsibility for cable damage during re-entry.

Cable Suitability

Both GreyStuff and RedStuff are single-component, solvent-free systems that do not damage cable sheaths or stain duct surfaces.

Storage & Shelf Life

Store in a cool, dry environment away from sunlight.

Shelf Life: 12 months unopened

Once opened: product can be reused for 1 month if the screwcap is sealed securely.

FAQs

What makes DuctSeal FR different from other fire-rated duct sealing systems?

DuctSeal FR is built on our patent pending intumescent tube system, manufactured from FireStuff marine grade granulate. Unlike traditional putties or foams, these modular tubes can be linked, separated, or reconfigured for trefoil/triplex cable arrangements, ensuring both fire integrity and cable stability. Combined with our GreyStuff and RedStuff intumescent compounds, it provides a re-enterable, LSZH, and MEKO-free solution that is unmatched in flexibility and performance.

How long is DuctSeal FR fire rated for?

When installed as per test conditions, DuctSeal FR provides up to 4 hours (240 minutes) of fire resistance in both directions, tested to BS EN 1366-3:2021 and AS 1530.4:2014.

What standards does DuctSeal FR comply with?

DuctSeal FR is fully compliant with:

- BS EN 1366-3:2021 (fire resistance)

- AS 1530.4:2014

- DSEAR & ATEX (explosive atmospheres)

- WIMES & Sewers for Adoption (water industry)

- APEA Blue Book & DCG (petrol forecourts and utilities)

Is DuctSeal FR low smoke and halogen-free?

Yes. DuctSeal FR is a low smoke, zero halogen (LSZH) system, making it suitable for enclosed environments such as data centres, tunnels, transport hubs, and substations.

What is the difference between GreyStuff and RedStuff?

GreyStuff is the standard sealant tested as part of the BS

EN 1366-3:2023 fire tests.

RedStuff has the same formulation with the exception of

pigment (<1% difference). It has not been independently fire tested but can

be used with customer or end-user authorisation.

Both compounds provide the same fire, gas, and water

resistance, and the colour difference does not affect performance or safety.

Can DuctSeal FR be re-entered for cable upgrades?

Yes. DuctSeal FR is a re-enterable duct sealing system. Once cured, the sealant reaches a rubber-like hardness that can be cut or removed for future cable works. Always ensure cables are de-energised before re-entry.

Does DuctSeal FR resist gases and chemicals?

Yes. It has proven resistance against toxic gases (methane, chlorine, hydrogen sulphide) and hydrocarbons, making it suitable for both water utilities and petrol forecourt installations.

Does DuctSeal FR reduce cable performance?

No. At a 25mm seal thickness, thermal resistance is only 5.1 K/W, ensuring minimal cable de-rating and allowing cables to operate at full current capacity.

Can DuctSeal FR be installed in damp conditions?

Yes. The duct and cables can be damp, but they must be free from running water, dirt, oil, or grease before installation. For ducts with flowing water, we recommend using a Kraso Mechanical Seal.

Where is DuctSeal FR manufactured?

All components of DuctSeal FR are proudly designed and manufactured in the UK, ensuring high quality, supply chain reliability, and compliance with British and European standards.

Why choose AC Cable Solutions for fire-rated duct sealing?

AC Cable Solutions provides British made, industry-compliant sealing systems, backed by independent fire test certification, WIMES approval, and a dedicated technical support team. We ensure fast delivery, trusted advice, and long-term protection for every project.