DuctSeal LG Cable Duct Sealing System

DuctSeal LG Cable Duct Sealing System

Couldn't load pickup availability

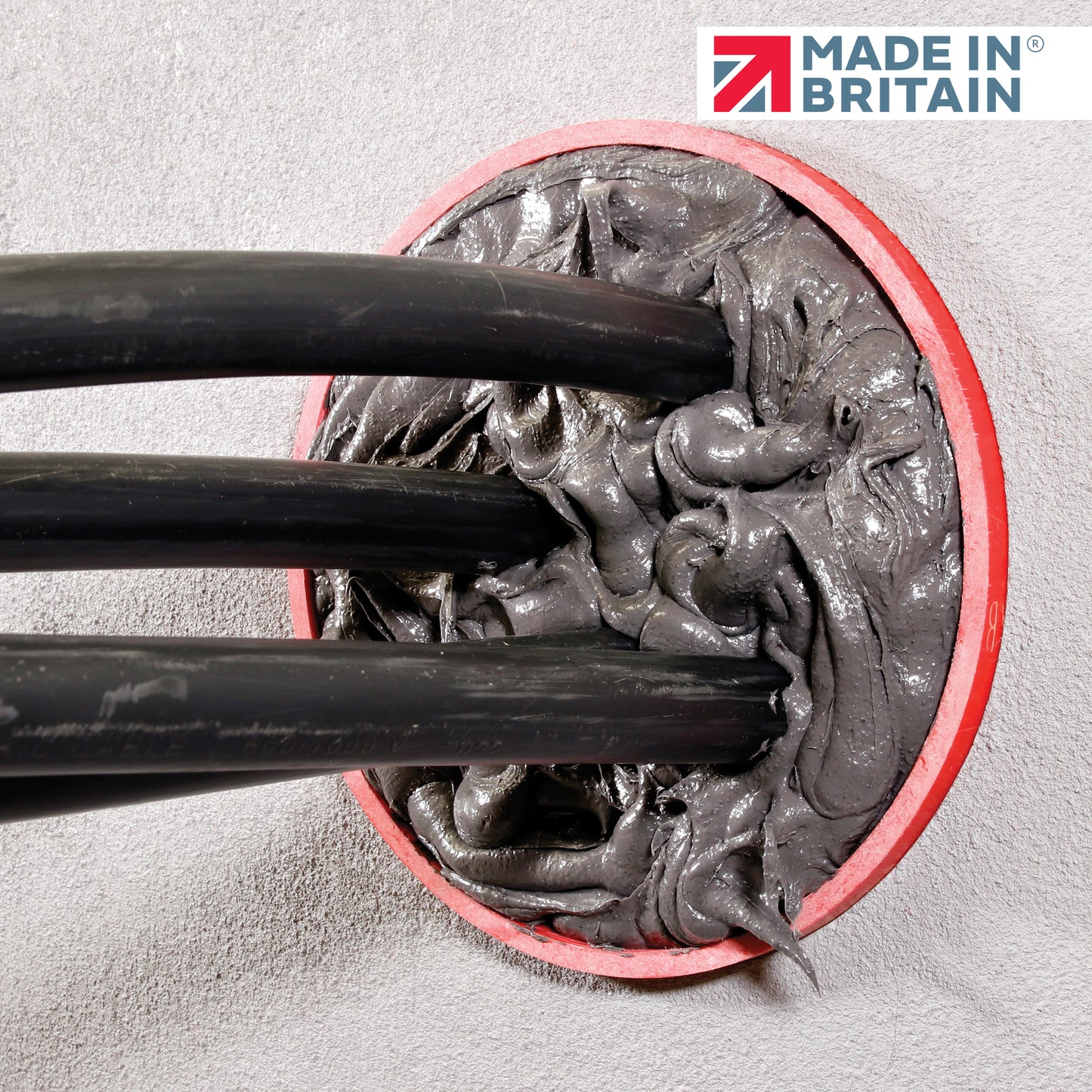

The DuctSeal LG Cable Duct Sealing System is a high-performance, re-enterable duct sealing solution designed for sealing single or multiple cables and small pipes within ducted networks.

Engineered for applications where gas, air & watertightness are essential, DuctSeal LG prevents the ingress of groundwater, harmful gases, flammable vapours, and vermin while maintaining flexibility for future access.

Trusted across the water industry, gas utilities, telecoms, power distribution, and civil engineering sectors, this UK-manufactured duct seal system ensures long-lasting protection and compliance with industry requirements.

Each DuctSeal LG kit includes our unique daisy-chained foam tubes that wrap around and separate cables, providing a secure fit and minimising cable movement. The system is completed with either GreyStuff or RedStuff, our advanced, intumescent, halogen-free, MEKO-free sealing compound, specially formulated for durable, flexible performance.

Share

| FEATURE | Density | Colour | Skin Over Time | Curing | Tack Free Time | Hardness | Elongation | Flow | Tensile Strength | Operating Temp. | Temp. Resistance | Intumescence Activation Temp. |

Pressure Resistance | Shelf Life |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| VALUE | 1.27 | Grey or Red | 10 mins | 3-4mm per day | 22 mins | 35 to 38 Shore A | 250% | 3.33 million cPs at 380°C |

0.72N/mm² | +5 to 40°C | -35 to +120°C | 210°C | 1.0 Bar | 12 months |

Collapsible content

Key Features

Revolutionary Cable Support System

Unique backing design provides enhanced cable stability, reducing strain and movement within the duct.

Safe, MEKO-Free Formulation

Our advanced FyBrid sealing compound is non-hazardous, halogen-free, and environmentally friendly, delivering a secure and safe seal without harmful emissions.

High Pressure Resistance

Engineered for robust performance with proven sealing capability of up to 1.0 bar, suitable for a wide range of underground and pressurised environments.

Chemical Resistance for Utilities

Tested and effective against methane, chlorine, and hydrogen sulphide, making it ideal for water industry infrastructure and utility networks.

Hydrocarbon Protection

Suitable for petrol forecourts, fuel distribution sites, and other hydrocarbon-exposed environments, offering durable sealing performance.

Full Compliance with Industry Standards

Meets or exceeds DSEAR, WIMES, DCG, APEA Blue Book, and ATEX requirements for safety and performance.

Enhanced Hygiene Protection

Formulated to resist bacterial and fungal growth, ensuring long-term reliability in damp or contaminated ducts.

Minimal Cable De-Rating

With a 20mm seal thickness, thermal resistance is just 5.1 K/W, allowing cables to retain their full current-carrying capacity.

Watertight Barrier Protection

Prevents water ingress and protects against cable degradation and water treeing, extending cable lifespan.

British Made Quality

Proudly designed, developed, and manufactured in the UK, ensuring excellent adhesion, durability, and consistent performance.

Fast & Simple Installation

Designed for quick application in multiple cable scenarios, without the need for special tools.

Installation

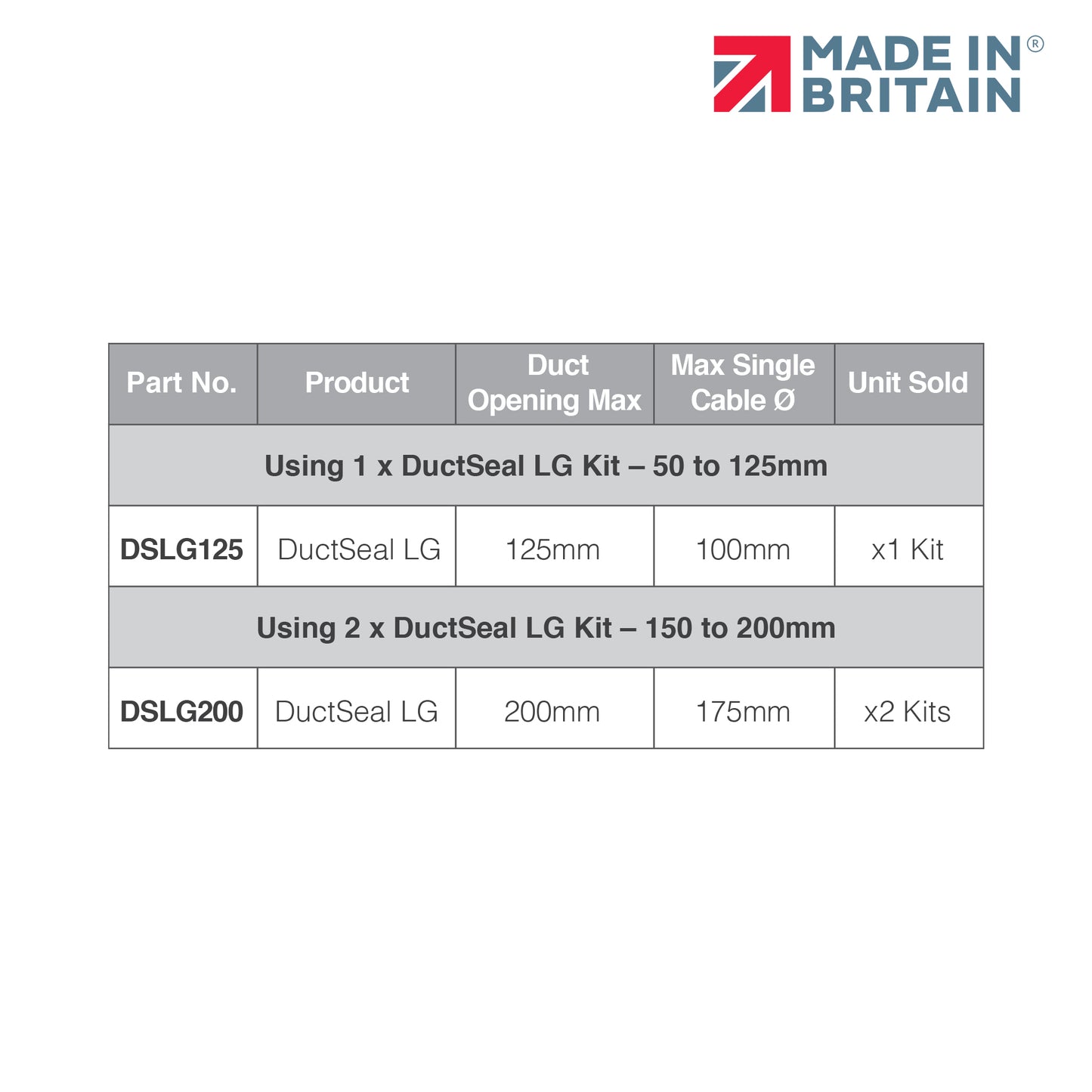

One Kit Per Duct

Each kit includes all components required to seal one duct, based on the kit size selected.

Note: A standard caulking gun is required (not included but available separately). Depending on the cable fill percentage, one kit may seal more than one duct. For advice, contact our technical team on +44 (0)161 874 1480.

Cable Separation & Support

Correct separation is essential for performance. The patent-pending tubular rubber backing system can be configured in continuous strips, rings, or cross-shapes to provide support and separation for large single-core, trefoil, or triplex cables. This ensures safe spacing, prevents movement, and guarantees DSEAR-compliant trefoil sealing.

Running Water Conditions

For best results, ducts and cables must be dry and free from running water. Clean surfaces of all dirt, oil, and grease before applying GreyStuff or RedStuff. If running water is present, please call +44 (0)161 874 1480 for technical advice. In most cases, we recommend using a Kraso Mechanical Seal.

Cure Time

GreyStuff and RedStuff cure at approximately 3–4mm per day, depending on humidity and temperature. Higher humidity and warmer conditions accelerate curing.

Minimum seal depth: 20mm for effective performance.

Cleaning

Uncured material can be removed using solvent-based wipes. Once cured, the compound must be removed mechanically.

Health & Safety

Both GreyStuff and RedStuff are based on a neutral curing, MEKO-free system, making them non-hazardous and installer-safe during application.

Compliance

DuctSeal LG is fully compliant with:

- WIMES (Water Industry Mechanical & Electrical Specifications)

- APEA Blue Book (petrol forecourts)

- ATEX & DSEAR (explosive atmospheres)

- DCG (Ducted Cable Guidance)

- Sewers for Adoption

- Network Rail PADS

Re-Entry & Removal

Once cured, the compound has a hardness similar to a rubber eraser. This allows ducts to be re-entered or resealed when required.

Always use sharp tools on de-energised cables. AC Cable Solutions accepts no responsibility for damage caused during re-entry.

Cable Suitability

GreyStuff and RedStuff are solvent-free, single-component systems that do not damage cable sheaths or stain duct surfaces.

Storage & Shelf Life

Store in a cool, dry location away from direct sunlight.

Shelf Life: 12 months unopened

After opening: reseal tightly and use within 1 month.

FAQs

What makes DuctSeal LG different from other duct sealing systems?

DuctSeal LG combines unique daisy-chained circular foam backings with a flexible, intumescent, MEKO-free sealing compound (GreyStuff). This design delivers superior stability, prevents cable movement, and ensures long-lasting resistance against water ingress, toxic gases (methane, chlorine, hydrogen sulphide), hydrocarbons, and microbial attack. It is also fully compliant with WIMES, ATEX, DSEAR, and APEA standards, making it one of the safest and most reliable duct sealing solutions available.

Is DuctSeal LG safe to use in all environments?

Yes. DuctSeal LG is non-hazardous, halogen-free, and MEKO-free, ensuring safe installation in sensitive environments such as water treatment plants, data centres, telecom networks, petrol forecourts, and industrial facilities.

Can DuctSeal LG be used for retrofitting existing installations?

Absolutely. DuctSeal LG is a re-enterable duct sealing system, which means it can be installed during new projects or retrofitted into existing ducts. Future re-entry for cable upgrades or maintenance is straightforward and safe.

Is DuctSeal LG WIMES compliant?

Yes. DuctSeal LG complies with WIMES 3.02 (2019), clause 6.4.3.2(d), and is approved for use by all UK and Irish water authorities.

Can DuctSeal LG withstand chemicals and hydrocarbons?

Yes. DuctSeal LG is designed to resist a wide range of aggressive agents, including methane, chlorine, hydrogen sulphide, and hydrocarbons. This makes it suitable for petrol forecourts, wastewater plants, sewage pumping stations, and industrial sites.

How much pressure can DuctSeal LG withstand?

When installed correctly, DuctSeal LG achieves a gas- and water-tight seal up to 1.0 bar pressure, providing strong protection even in challenging environments.

How long does DuctSeal LG take to cure?

Cure rate is approximately 3–4mm per day, depending on humidity and temperature. A minimum of 20mm seal depth is required for full performance.

Does DuctSeal LG reduce cable performance?

No. At a 20mm seal depth, the thermal resistance is just 5.1 K/W, which means minimal cable de-rating and no loss of current-carrying capacity

How long will the seal last?

DuctSeal LG is designed for long-term durability in harsh underground and industrial conditions. With correct installation, it provides decades of service life, protecting cables against water treeing, chemical ingress, and environmental degradation.

Why choose AC Cable Solutions?

AC Cable Solutions is the exclusive UK & Ireland distributor of KRASO GmbH and the manufacturer of the GreyStuff & RedStuff sealing compound. All products are British made, rigorously tested, and compliant with international standards, ensuring the highest level of safety and performance. Our dedicated support team provides technical advice, training, and next-day delivery to keep your projects moving.